About us

Steel, Alloy Steel, Stainless Steel, Heat Resistant Steel & SG Iron Castings Manufacturer

What We Do

Steel, Alloy Steel, Stainless Steel, Heat Resistant Steel & SG Iron Castings Manufacturer

Parikh Metacast Pvt. Ltd. is an ISO 9001:2015 certified company and an associated company of 25 years old Parikh Metaliks Pvt Ltd.

We manufacture steel, alloy steel, stainless steel, heat resistant steel and SG Iron castings 400 kgs to 7000 kgs single piece. We have been manufacturing & supplying various critical castings for industry segments like Crusher Manufacturers, Thermal power projects, Automobile Tool-room, Marine & Shipbuilding division, Power & Transmission, Cement machinery, Steel plant equipment manufacturers, Material handling equipment manufacturers, Pump & Valves manufacturers etc. Majority of our components are being supplied in finish machined condition with relevant NDT testing (like UT, MPI, RT) done. We are also approved by ABS (American Bureau of Shipping) & IRS (Indian Register of Shipping) for manufacture of steel castings for Marine/Shipbuilding projects.

Our facilities are designed to meet variable requirements in terms of size, weight, criticality and grades of Steel and Ductile Iron. This enables us to take up challenging cast components having weight range up to 7000 kg and almost all grades of Steel, Stainless Steel, Alloy Steel & SGI.

Our facility is also been approved by L&T MHPS Boilers Pvt Ltd, Metso Minerals Ltd, Elecon Engineering for their regular requirement of castings. We recently have supplied one casting to M/s Nihal Industries in C-45 which was weighing @ 7.2MT. We are very keen on developing critical castings & supplying in proof/finish machined condition. We are confident of meeting stringent QA requirements given an opportunity.

We have always kept the growing ‘Customer Satisfaction Index’ as our TOP PRIORITY.

Our Foundry Capability

Material

- Steel

- Alloy Steel, Stainless Steel

- Heat Resistant Steel

- SG Iron (Ductile)

Value Addition

- Heat Treatment

- Machining

- Auto Quenching (Water)

- Sub-assembly

Casting Range

- Weight : 400kgs to 7000kgs single piece, Quenching (Water)

Annual Volume

- Volume : 4500 MT

Our Core Ideology

Our Mission

We produce various steel, alloy steel, stainless steel, HRCS & SG Iron castings ranging from 400 kgs to 7MT single piece for Crusher Manufacturers, Automobile Tool-room, Planetary gearbox, Pumps & Valves, Thermal Power plants & Material Handling & provide end to end solutions from patterns to machined parts to our customers with a team of technically competent & motivated employees

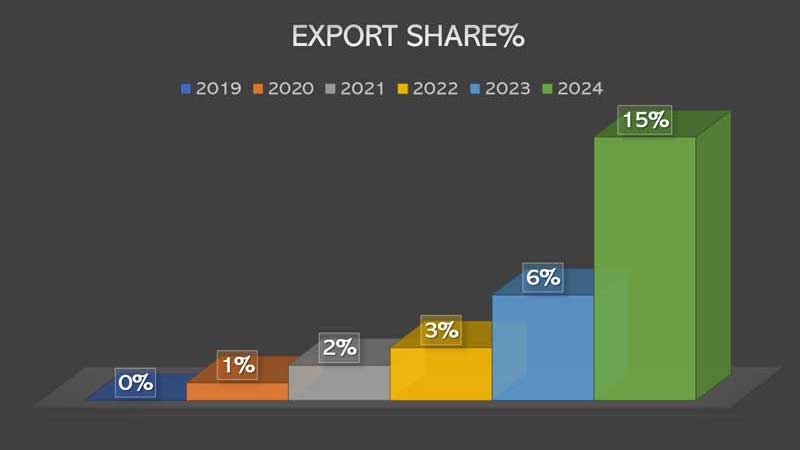

Global reach

No geographical barriers can stop us from performing the best. Even though our customers are all over the world. The distance is no barrier when it comes to ensuring high-quality service. Our products get exported in countries like the USA, Qatar, Dubai, Japan.

Our Strengths

- Varity of casting range i.e. upto 7MT single piece & takes challenging work.

- End to End solution i.e. from pattern to Finish Machining.

- Inhouse Facilities to meet Machining & NDT requirements.

- Numerous Third Party inspection agency approvals.

- Competitive price with committed delivery.

- Self-motivated team which drives to save customer cost.

Our Leadership

Samir Parikh (MD & CEO)

He completed his formal graduation in Mechanical Engineering from COEP, Pune & started a foundry named "Parikh Metaliks Pvt Ltd" in Gokul Shirgaon MIDC in 1998 in Kolhapur. In less than a decade of his hard work, dream, initiatives & inquisitive behaviour flourished his & teams enterprise into Parikh Group of industries.

His expertise, strong foundation of ethics and leadership have led the group to its successful position today. With a keen eye for cutting edge technology implementation & quality output he has ensured consistent growth in customer satisfaction index and thereby increased in business volumes. Other than his business accomplishments, he has also been the Chairman of Indian Institute of Foundryman (IIF) Kolhapur Chapter.

Nirmit Parikh Director

He is the second generation of the Group. Driven with Passion, Interest & Eagerness in joining the Foundry Family business has made the group reach on a Global Platform now. He had been involved in setting up this dream project "Parikh Metacast Pvt Ltd" with his father as a Project head & executed the Project with his team in 1.3 years.

He is a B-tech Mechanical Graduate & has gained experience in a Foundry to learn the aspects of the Group's operation & systems. With his skills honed, he has become an indispensable part of the group. He has kept in tune with the ethos of the group & he believes that a successful business can be built through strong relationships & ethics.

Our Team

Our team of Designers, Technical Engineers & Employees are the best in their own way & we promise to provide quality castings & services to our esteemed customers. These 120+ competent employees are trained regularly so that they are upgraded with latest foundry trends, customer requirements & latest technology which enables them to become multi tasker & best in providing the end results

Our Infrastructure

The manufacturing process and systems of Parikh Metacast are best accepted internationally. The industry comprises state of the art facilities for molding, melting, shot blasting, fettling, machining and assembly of engineered castings and components under one roof. Our testing and inspection infrastructure include pyrometer, well equipped sand testing lab, UTN Machine with extensometer and computerised optical spectrometer for chemical analysis up to 21 elements during melting sequence ensures chemistry of molten metal to suit diverse range of steel castings, alloy steel castings and stainless steel castings for different applications

-

Heat Treatment Furnace

-

Moulding -Continuous Sand Mixer

-

Melting-Induction Melting Furnace

-

Testing and Inspection

-

Sand Reclamation Unit

-

Dust Extraction system

We Promise

- Benefits to Our Esteemed Customers & Employees

- Sustain & Improve Our Environment

- Transparent Communication

- Quality Product

- Fair Price

- Timely Delivery

Recognition

We have vast experience of catering to casting requirements under 3rd party inspections

Best Small Business District Award 2017

Overall Business Excellence award from TLC